Factories

In the industrial world, noise is often considered an unavoidable byproduct of progress. But excessive noise isn't just a nuisance - it's a hazard. Prolonged exposure to high decibel levels in factories can lead to hearing loss, increased stress, reduced concentration, communication breakdowns, and serious safety risks. At Himalyan Acoustics, we approach industrial acoustics and factory acoustic treatment not just as a technical challenge but as a mission to build healthier, more efficient environments.

Factories are filled with machines, motors, compressors, blowers, stamping equipment, and high-speed processes that generate continuous broadband noise, often peaking at dangerous SPL levels above 90–110 dB(A). When this noise reflects off hard surfaces like concrete, metal, or glass, it creates a reverberant sound field that compounds the problem for that factory acoustic treatment is essential.

❌ Hearing damage and fatigue for workers

❌ Difficulty in voice-based communication or emergency alerts

❌ Reduced concentration and human error

❌ Regulatory non-compliance (OSHA/ISO noise limits)

❌ Increased absenteeism and lower productivity

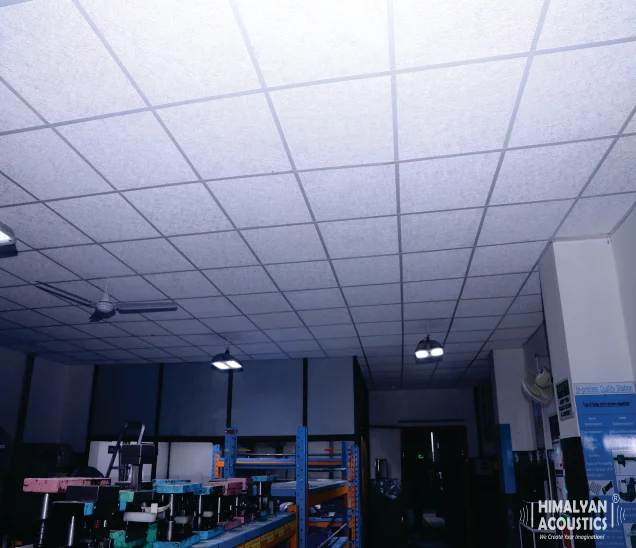

1. Reverberation Control (RT60 Reduction): Hard surfaces in factories cause noise to bounce and linger. Reducing reverberation time ensures sound energy dissipates quickly, lowering the overall noise floor. We target RT60 values under 1.0 seconds in typical large halls.

2. Localized Sound Absorption: We deploy high-density absorber panels (like our Absorb Wool or Aphony Fibrette) in zones where noise is most intense: near compressors, stamping lines, grinding areas, etc. These absorb mid- and high-frequency energy, helping create “quiet pockets” for operators.

3. Barrier-Based Isolation: In open floor plans where machines and humans coexist, acoustic barriers or enclosures help prevent direct sound paths. Our custom-built composite partitions combine sound-blocking mass layers with absorbing cores for hybrid isolation.

4. Machine Enclosures: For boisterous equipment, we design modular acoustic enclosures lined with broadband absorbent materials fitted with ventilation silencers and access panels for maintenance. These enclosures can reduce emitted noise by up to 20–25 dB(A).

5. Vibration and Structural Integrity: Industrial machinery generates vibrations that can affect the building structure and equipment lifespan. Acoustic and vibration control measures help protect infrastructure and improve equipment durability.

Compliance & Measurement: All solutions are designed to meet ISO 11690 (Acoustics – Guidelines for noise control in factories), OSHA workplace limits, and local environmental regulations. Using reverberation mapping, SPL zoning, and sound decay analysis, we ensure measurable, certifiable improvements in factory acoustics.

️ Retrofit or New Construction – We Deliver Both: Whether you're building a new industrial unit or retrofitting a decades-old factory floor, our team integrates acoustic treatment without interrupting workflows. Our prefabricated panels and modular kits ensure rapid deployment even during non-stop shifts.

Safety, Compliance, and Mental Clarity: Noise doesn't just hurt ears - it clouds minds, disrupts communication, and puts workers at risk. Our industrial acoustic solutions aren't just for decibel reduction - they're for human protection, task clarity, and long-term operational excellence. From pharmaceuticals to steel plants, from garment factories to power substations - Himalyan Acoustics is trusted by industry leaders to bring silence where it matters most.